How do you figure how the concrete you need for a job?

Chances are, you stumbled in here thinking there was some kind of table telling you how many bags of concrete you need for a do it yourself home job, but that’s not what we’re talking about today. So if you want that table to calculate how much concrete you need, just skip to the bottom for general rules of thumb.

Today, we want to talk about how the professionals determine how much concrete we need for a job.

We’re going to pull back the curtain a little bit (not too much, because we don’t want to lose you in technical jargon) enough for you to see the concrete project planning process that goes on for our estimators right after we take down some initial numbers and photographs from any project we get offered.

This process is usually broken down into two parts, determining how much material we need, and what kind of material we need to complete the project.

You might not know it, but this entire process isn’t driven by us as estimators, project managers or operations managers. Even though we all handle the project at different points: YOU are the one who drives the entire process.

It’s your goals we’re trying to reach, and ultimately the success of the project is judged by your standards.

Don’t Think About Cost First, Think About the Results First.

Since you are the one in the driver’s seat here, the more we know about your specific needs, the better your concrete project is going to be. The question of cost is an important one, but it’s more important that you got your money’s worth.

You only get your money’s worth if you have a very open dialogue about your goals with your estimator. What is it you’re trying to achieve?

Think not only about the thing itself “a parking lot” but think about the people using the parking lot. What kind of a parking lot would serve that best?

Think about the traffic on your industrial loading dock. What kind of traffic is going to be using the loading dock? How often is that loading dock going to be used?

Think about the goal not in terms of the thing itself, but in terms of how the thing is used and how you want people to feel using it. Ease of use. Durability. Accessibility. These are the questions that you’re going to need the answers to in order to get that precise result you’re looking for so you really feel like you got your money’s worth.

You can start asking those questions and getting the real answers here by submitting an estimate request. No runaround. Just straight answers.

Don’t Look for Hacks, Because There Aren’t Any.

Here’s the last thing before we get into the nitty-gritty. There’s no “hack” that’s going to help you out here. Goodmanson Construction isn’t in the business of selling magic bullets or miracle cures or anything like that.

We’ve been in the concrete, asphalt and excavation business for going on 50 years. We’ve got the tools and technology to get the job done and get it done right.

But what “doing it right” means is different for different projects. So really, give a lot of thought to what you want to accomplish with the project. Give a lot of thought to how you want this new thing to be used.

That’s how we get started. Now let’s get after it.

Determining Concrete Volume

This is pretty easy in the abstract. You take the area you want to pour the concrete and the depth you want to pour the concrete and viola: you get the cubic feet of concrete you’re looking to pour.

We calculate the volume of concrete you need based on three simple factors: the width by the length by the depth of the area where the concrete needs to be poured. This can get tricky when you’re measuring spaces that aren’t exactly square, and account for things like grade and slope.

But volume always comes down to the same formula. Cubic Feet. Length by width by depth.

Determining Concrete Mix

This is where the fun really starts.

If you’re doing this yourself at your home, you’re probably not going to be considering concrete mix. Concrete is concrete, right? Not for when you’re doing industrial concrete or commercial concrete projects! This is where the big boys play.

What’s great about the concrete industry now is the customization of mixes. We can, through our suppliers, customize a perfect mix to every project. And these mixes are customized for PSI, slump, color and texture.

Concrete PSI

PSI is an abbreviation we use for measurement called Pounds per Square Inch. What do you use that measurement for? You use it to measure the amount of pressure that a material can withstand before failure. You have a PSI rating in your tires on your car or bicycle. You have it in a basketball or football.

What happens when you push a football past its PSI limit? It bursts! That’s a failure. For concrete, that means a certain mix can withstand a certain amount of pressure before it fails and breaks or cracks.

How do you measure something like that? It’s something best left to the pros… all our suppliers have testing equipment that puts compressive pressure on their concrete samples. They keep increasing the pressure until the concrete sample fails, and then they record that as the maximum PSI for the sample.

Not exactly something you can try at home!

Concrete Slump

Another measurement you may not have heard of is “slump.” This is a measurement that’s particular to the concrete industry but concrete slump is a measurement of the consistency or workability of a material like concrete.

What we do to get that measurement is we perform a slump test. A simple slump test can be performed on site with a specialized cone and tamper. You could probably even do one at home! You pour the mixed concrete into the cone, tamp it a bit, then remove the cone.

Viola! You can now measure the slump!

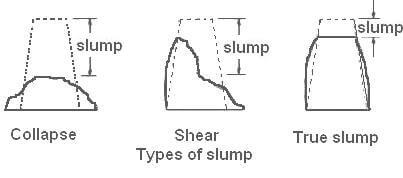

You measure slump from where the top of the cone was to where the top of the concrete is. If it collapsed totally, that’s “collapse” slump. If part of it collapsed and some of it stood up, that’s “shear” slump. If the whole thing stood up and held shape, that’s called “true” slump. With “shear” slump, you do the measurement from the top of the cone to the bottom of where the concrete collapsed.

Very dry mixes having slump 0 – 25 mm (0 – 1 inch) are typically used in road making, low workability mixes having slump 10 – 40 mm (about .25 inch – 1.5 inches) are typically used for foundations with light reinforcement, medium workability mixes with slump 50 – 90 mm (2 inches – 3.5 inches) , are typically used for normal reinforced concrete placed with vibration, high workability concrete with slump > 100 mm (4 inches) is typically used where reinforcing has tight spacing, and/or the concrete has to flow a great distance.

So what does that mean?

There is a relationship between the strength of the concrete (measured in PSI) and the slump of the concrete (measured in inches or millimeters) but we’re not going to go too far into it here.

Most of the time, we’re pouring concrete outside for industrial projects that have to run multiple ton trucks over the surface 24 hours a day. Or we’re pouring parking lots that have cars all hours of the day or night.

We also use steel rebar reinforcement and with some projects we even have used fiber reinforced concrete. We also insulate our concrete, because when we put concrete down, it stays down!

How to estimate concrete for Small Projects

What you’ve just read is about the big stuff. The stuff that professionals really should take care of for commercial and industrial companies.

But if you’re just looking at a small project at home that you think you can take care of without too much trouble, here are some handy tips for how to estimate what you need.

Always factor in depth. And have a plan for what to do with the material you excavate. It’s going to be a lot more than you think!

And if you’re getting into excavation, if it’s more than what you can do with a shovel, we’d recommend once again calling a professional to do the work, get the right permits, and get their heavy excavation equipment. If not used properly and without proper training, not only can it be unsafe but you can end up doing a lot of damage to your own property.

Goodmanson Construction has equipment operators with years of experience on all kinds of projects. Decades of experience combined with the latest technology means you’re not going to have to worry about whether we can do the job safely–we can and we do.

Think about the application in terms of what the concrete is going to be used for. Is it going to be mostly foot traffic? Are you going to try to put a vehicle on it? Is it indoor or outdoor? That’s going to determine the PSI you need for your concrete. The more weight and the more forces you’re going to subject the concrete to (read our blog on frost heaving for more on that) then the higher PSI you’ll need.

| Cubic Yards | Pounds of Pre-Mixed Concrete Needed |

| 1 | 132 |

Which works itself out to about 5 pounds of dry pre-mixed concrete per cubic foot.

Remember, when you get to commercial applications or industrial applications of concrete, all of this goes out the window. When you get to the commercial or industrial level of concrete work, you can’t think of it just in terms of “how many pounds do I need” or “how much concrete is required for x square feet” because that’s not going to get you to achieving your project goals.